|

This section is about:

Why Corrugated Plates ?

A corrugated plate is an example of a 3-dimensional or space structure.

Corrugated plates have enhanced resistance against horizontal and vertical

loads. To consider the effectiveness of corrugated plate look at the

following experiment.

Enhanced horizontal resistance

|

|

When a thin sheet of steel rests between two supports

it will bend due to the fact that it has insufficient strength to

carry its own weight. |

|

If the same piece of steel is corrugated then

it will be capable of supporting one hundred times its own weight.

|

|

|

|

If the load is increased past this point then the

structure will fail and the corrugations will flatten out. |

|

This problem can be rectified by using transverse

stiffeners at the ends. The corrugated plate acts as a beam and

can support even greater loads.

|

|

Enhanced vertical resistance

|

|

When a thin sheet of steel is stressed to a vertical

load, the plate will bend due to the fact that it has too less capacity. |

|

The profiling of the plate avoids failure, due

to enhanced resistance against vertical loads.

|

|

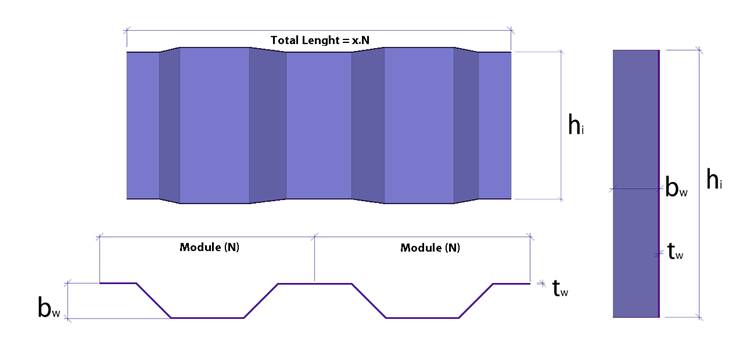

Corrugated Plate dimensions

| The figure below shows our standard corrugation. Other dimensions

are also possible. Please contact us. |

|

|

Our patented production process doesn't require moulds

and therefore we are able to manufacture all dimensions between module

500 mm and 1000 mm. In our standard configuration the angles are 45

º. But angles of approximately 70 º can also be achieved.

Our corrugated plates are unlimited of length. The plates have no theoretical

limitations in the number of folded modules.

The folded modules have to be transported, so in practice the lengths

are ranging between 6 m and 18 m.

The next chart will give a summarize of our product range:

|

Product specification

|

Material thickness:

|

1.5 - 12 mm |

| Height:¹ |

max. 4 m |

| Depth: |

max. 240 mm |

| Angle: |

max 70 º |

| Deformation: |

5 x r/t |

| Material: |

steel, aluminium, stainless steel |

| Length:² |

18 m |

¹ Height is also called length in press-brake terminology

² Length is also called width in press-brake terminology

Corrugated Plate shapes

| |

| There are several varieties of corrugation shapes.

All shapes which continuously repeat can be manufactured by GLP.

The only condition is a maximum depth of 240 mm. |

|

Corrugated Web Beams

A Corrugated Web Beam or a GLP Beam is a built-up

girder with a thin-walled, corrugated web and plate flanges. The

profiling of the web avoids failure of the beam due to loss of

stability before the plastic limit loading of the web is reached.

Engineers have long realized that corrugations in webs enormously

increase their stability against buckling and can result in very

economical designs. Therefore, Corrugated Web Beams have

the potential to eliminate many costly web stiffeners. In addition,

the use of thinner webs results in less raw material cost with

savings estimated at 10-30% compared with conventional built-up

sections and more than 30% compared with standard I-beams.

The optimum area of application is in steel structural engineering

wherever rolled profiles of structural height greater than 800

mm or lattice girders above 1500 mm were formerly used.

Within the subject of girders there are again many applications.

For fatigue applications such as bridges etc., it is thought

that sinusoidal corrugations are better than trapezoidal

corrugations. This is not the case for GLP corrugated plates.

GLP is able to bend the plates with a radius/thickness rate greater

than the number 5.

|

| |

| |

| |

| |

| |

|

|

| |

| |

| |

| |

|

|

Applications

Corrugated web beams are manufactured to meet the markets highest requirements.

The beams and the corrugated plates are suitable as:

- supports and columns

- steel retaining walls

- transportation structures (such as the side panels of trains, containers

and trucks)

- feed silos

- cranes

- double-hulled ships

|

|

Hybrid Construction

The aim is to take advantage of different materials. The concrete

is used for the deck and the bottom slab. The webs have only to

connect the cross section and to transfer the transverse forces.

For this a corrugated plate is used.

|

|